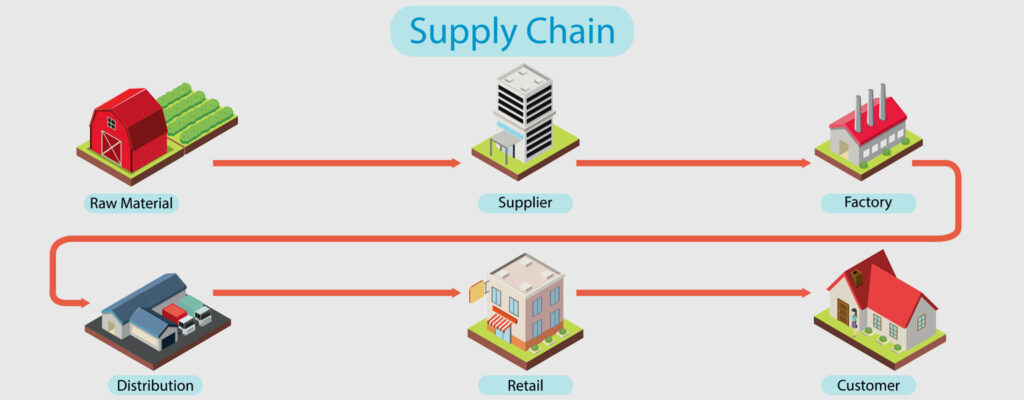

Supply chain optimization involves enhancing the efficiency, resilience and effectiveness of the entire supply chain network to achieve strategic goals, meet customer demands, and drive competitive advantage. Here’s a breakdown of key components and strategies involved in supply chain optimization:

Network Design and Configuration

- Analyzing and optimizing the network structure, including the number and location of facilities (e.g., manufacturing plants, warehouses, distribution centers) to minimize transportation costs, lead times, and inventory levels.

- Considering factors such as customer locations, demand patterns, supplier locations, transportation infrastructure, and labor availability in network design decisions.

Inventory Management

-

Implementing inventory optimization strategies to balance inventory levels with customer service levels and cost considerations.

-

Utilizing techniques such as demand forecasting, safety stock optimization, reorder point calculation, and inventory segmentation to optimize inventory across the supply chain.

Demand Planning and Forecasting

-

Improving accuracy in demand forecasting through the use of advanced forecasting models, data analytics, and collaboration with customers, suppliers, and partners.

-

Incorporating factors such as seasonality, market trends, promotions, and external factors (e.g., economic conditions, geopolitical events) into demand planning processes.

Supplier Relationship Management (SRM)

-

Strengthening relationships with key suppliers through collaboration, communication, and mutual value creation initiatives.

-

Implementing supplier performance measurement and evaluation systems to monitor supplier performance, quality, delivery reliability, and responsiveness.

Transportation Optimization

-

Optimizing transportation routes, modes, and carriers to minimize transportation costs, transit times, and carbon emissions.

-

Leveraging transportation management systems (TMS), route optimization software, and real-time visibility tools to improve transportation efficiency and visibility.

Warehousing and Distribution Optimization

-

Streamlining warehouse operations and layout design to improve storage density, order picking efficiency, and labour productivity.

-

Implementing warehouse management systems (WMS) and automation technologies (e.g., robotics, automated storage and retrieval systems) to optimize warehouse processes and reduce fulfillment lead times.

Lean and Six Sigma Principles

-

Applying lean manufacturing and Six Sigma methodologies to identify and eliminate waste, variability, and inefficiencies in supply chain processes.

-

Implementing continuous improvement initiatives, value stream mapping, and Kaizen events to drive process optimization and performance excellence.

Risk Management and Resilience

-

Identifying and mitigating risks across the supply chain, including supply chain disruptions, geopolitical risks, natural disasters, and cyber threats.

-

Developing contingency plans, business continuity strategies, and supply chain resilience frameworks to enhance the ability to respond to and recover from disruptions.

Technology Integration

-

Leveraging advanced technologies such as big data analytics, artificial intelligence (AI), machine learning (ML), Internet of Things (IoT), and blockchain to enhance supply chain visibility, agility, and decision-making capabilities.

-

Integrating supply chain management systems with enterprise resource planning (ERP), customer relationship management (CRM), and other business systems to enable seamless data exchange and collaboration.

Sustainability and Environmental Considerations

-

Incorporating sustainability principles into supply chain operations, including reducing carbon footprint, minimizing waste, and promoting ethical sourcing and responsible manufacturing practices.

-

Adopting green logistics strategies, such as modal shift, route optimization, and eco-friendly packaging, to reduce environmental impact and promote sustainability.

By implementing these strategies and best practices, businesses can optimize their supply chain operations, reduce costs, enhance customer satisfaction, and gain a competitive edge in the marketplace. Continuous monitoring, analysis, and adaptation are essential to sustain supply chain optimization efforts and respond to evolving market dynamics and business requirements.

Supply chain optimization is the process of improving the efficiency and effectiveness of the supply chain by maximizing the flow of goods and services from suppliers to customers while minimizing costs and maximizing customer satisfaction. It involves analyzing and optimizing various components of the supply chain, such as inventory management, production processes, transportation, and distribution, to achieve better coordination, reduce waste, and enhance overall performance. By optimizing the supply chain, businesses can achieve higher levels of productivity, profitability, and competitiveness in the marketplace.

The term that represents supply chain optimization is “efficiency enhancement.”

Supply-based optimization is a strategy focused on maximizing the efficiency and effectiveness of the supply chain by primarily prioritizing the optimization of supplier-related processes and activities. This approach aims to enhance sourcing strategies, supplier relationships, and supply chain collaboration to ensure the timely and cost-effective delivery of goods and services to meet customer demand. By optimizing supply-based processes, businesses can improve inventory management, reduce lead times, minimize supply chain disruptions, and ultimately enhance overall operational performance and competitiveness.

Contact us at the Consulting WP office nearest to you or submit a business inquiry online.

Consulting WP really helped us achieve our financial goals. The slick presentation along with fantastic readability ensures that our financial standing is stable.